PDM Machinery’s conical grinding mill and thick powder mill used together are suitable to make and separate 0~0.5mm, 0~1mm,0~2mm,1~2mm ceramic and tile powder.

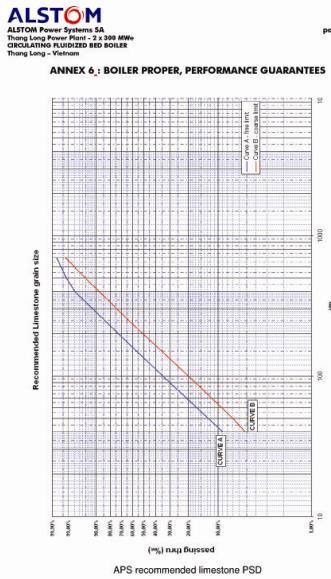

1. Global highest level CFB desulfurization powder grinding mill

2. Advanced thick powder separator

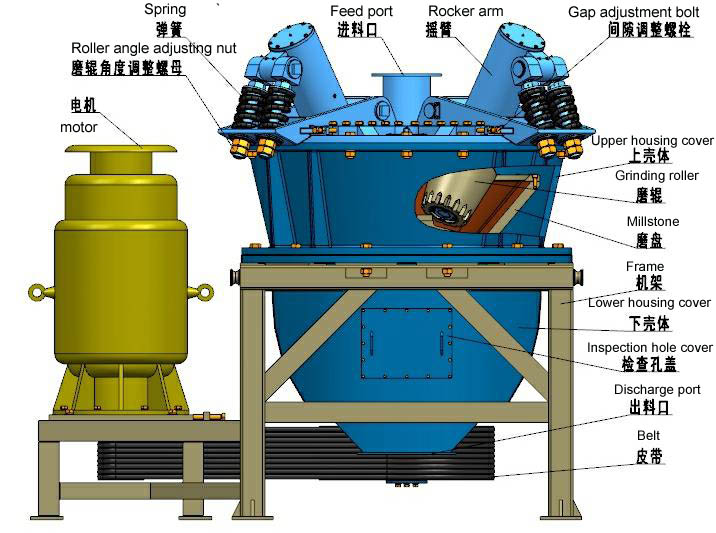

The structural features of GPM series disc mills:

The service life of roller bearing is long. The rocker arm device of GPM series generalized disc mill is fixed, the roller only rotates without revolution, the bearing force of grinding roller is single, and the working state is very stable. Thin oil circulation lubrication can also be used to improve the working environment of bearings.

The safety of the equipment is good. Using the bottom center drive, all the rotating parts are surrounded by the body, which will not bring hidden danger to the operator in any case.The service life of wearing parts is long. Using the mature surfacing technology of vulnerable parts of vertical mill, the wearing parts are not only wear-resistant, but also easy to repair, with low cost.

Working principle:

Material bed is pulverized repeatedly by rolling of the rollers.

Working principle of disck grinding millThe machine is vertical structure, including rotor device, roller mill device, force application device, feeding and discharging device, etc. The motor drives the grinding plate to rotate at a constant speed through the transmission mechanism. The material enters the mill through the feed port in the middle of the mill and falls on the center of the grinding plate. The uniform rotating grinding plate disperses and flattens the materials outward by the action of centrifugal force, forming a certain thickness and uniform material layer on the grinding plate. Under the action of centrifugal force, the material moves outward along the circumference of the grinding plate. At the same time, the material layer on the grinding plate is crushed by the roller pressure. The pressure of the grinding roller comes from the combined force of the pressure of spring or oil cylinder and the gravity of the grinding roller. Under the constant action of centrifugal force, the material layer on the grinding plate continuously moves to the top of the grinding plate, and the materials beyond the top of the grinding plate fall into the discharge port and discharge the mill under the action of gravity. In this way, a grinding is completed.

Equipment structure and characteristics

GPM series generalized disc mill is mainly composed of motor, planetary gear reducer and lubricating oil station (belt pulley is adopted for small model), grinding roller and rocker arm device, grinding disc device and lower shell.

Characters

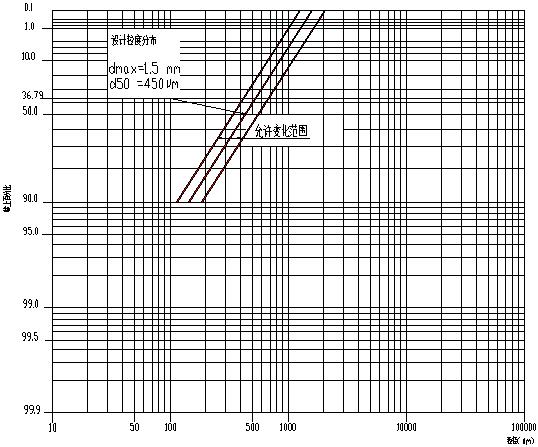

1. It can be controlled easily the grain size and distribution of output material by adjusting the height of the blocking cylinder, the spring pressure and milling gap.

2. The principle of material crushes material and middle working pressure(3-5MPa)make 50% powder size less than 1.5mm without any separation and avoid big energy consumption, noise and excessive impacted wear caused between roller and liner.

Waterfall thick powder separator

PDM Machinery’ conical grinding mill meets the requirement of the curve of limestone furnace grain size.