The selection method for the sealing and flushing system of chemical pumps

The selection method for the sealing and flushing system of chemical pumps is as follows:

1. Selection of sealing system

1.1 Sealing type

Mechanical seal: suitable for high pressure, high temperature, and corrosive media. Common types include single end face, double end face, and series connection.

Packing seal: suitable for low-pressure, low-speed, and non corrosive media, requiring regular maintenance.

1.2 Material selection

Sealing surface materials: commonly used silicon carbide, tungsten carbide, aluminum oxide, etc., should be selected according to the characteristics of the medium.

Elastic component materials: fluororubber, nitrile rubber, etc., need to consider the corrosiveness and temperature of the medium.

1.3 Operating conditions

Pressure: Double end face or series mechanical seals are recommended for high-pressure environments.

Temperature: High temperature resistant materials should be selected for high-temperature environments.

Medium characteristics: Corrosion resistant materials should be selected for corrosive media.

2. Selection of flushing system

2.1 Type of flushing

Plan 11: Extract fluid from the pump outlet to flush the sealed chamber, suitable for cleaning media.

Plan11 delivers high-pressure fluid from the pump outlet to the sealing chamber of the mechanical seal after being depressurized through a throttling or limiting orifice plate. Its main functions include:

Cooling: Reduce the temperature of the sealed chamber to prevent overheating.

Lubrication: Provide lubrication for the sealing surface to reduce wear.

Cleaning: Prevent particle accumulation and keep the sealing surface clean.

Plan11 is applicable to the following situations:

Cleaning medium: The medium is relatively clean and does not contain a large amount of solid particles.

High temperature medium: occasions that require cooling of sealed chambers.

High pressure pump: When the outlet pressure of the pump is high, Plan11 is suitable for use.

Plan 13: Extract fluid from the sealed chamber and return it to the pump inlet, suitable for easily vaporized media.

main features

Self circulation: The medium is led out from the pump outlet, throttled and enters the sealed chamber, and then returns to the pump inlet to form a circulation.

Cooling and lubrication: Remove the heat generated by the seal through the flow of the medium and provide lubrication.

Applicability: Suitable for cleaning media, and the inlet pressure of the pump is lower than the outlet pressure.

Application scenarios

Cleaning medium: Plan 13 is suitable for cleaning media without particles or crystals.

Low pressure inlet: The inlet pressure of the pump should be lower than the outlet pressure to ensure smooth circulation of the medium.

High temperature medium: effectively cooled and sealed through medium circulation, suitable for high temperature working conditions.

Plan 21: Rinse the sealing chamber from the pump outlet through the cooler, suitable for high-temperature media.

characteristic:

Medium circulation: using the pump outlet medium for flushing, without the need for external medium.

Cooling effect: By reducing the pressure and temperature of the medium through the throttle orifice plate, it is suitable for high-temperature media.

Self cleaning: Circulating flushing helps prevent particle accumulation and keep the sealed chamber clean.

Applicable scenarios:

High temperature medium

Clean or medium containing a small amount of particles

In situations where continuous cooling and lubrication are required

Plan 32: External cleaning fluid flushing sealing chamber, suitable for media containing particles.

1. Principle of Plan32 flushing

Plan32 flushing is achieved by introducing an externally clean flushing solution (usually water or other compatible liquid) into the sealed chamber of the pump, which serves the following purposes:

Flushing function: The flushing solution dilutes or carries away the medium inside the pump, preventing the medium from crystallizing, precipitating, or aggregating on the sealing chamber or sealing surface.

Cooling effect: The flushing liquid can reduce the temperature of the sealing chamber and prevent sealing failure caused by high temperature.

Lubrication function: Provide lubrication for the sealing surface and reduce wear.

2. Application scenarios for Plan32 flushing

The medium is prone to crystallization, precipitation, or polymerization (such as high concentration saltwater, polymer solutions, etc.).

The medium contains solid particles that may damage the seal.

The medium temperature is high and requires cooling of the sealed chamber.

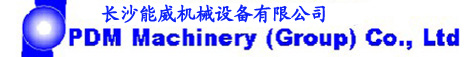

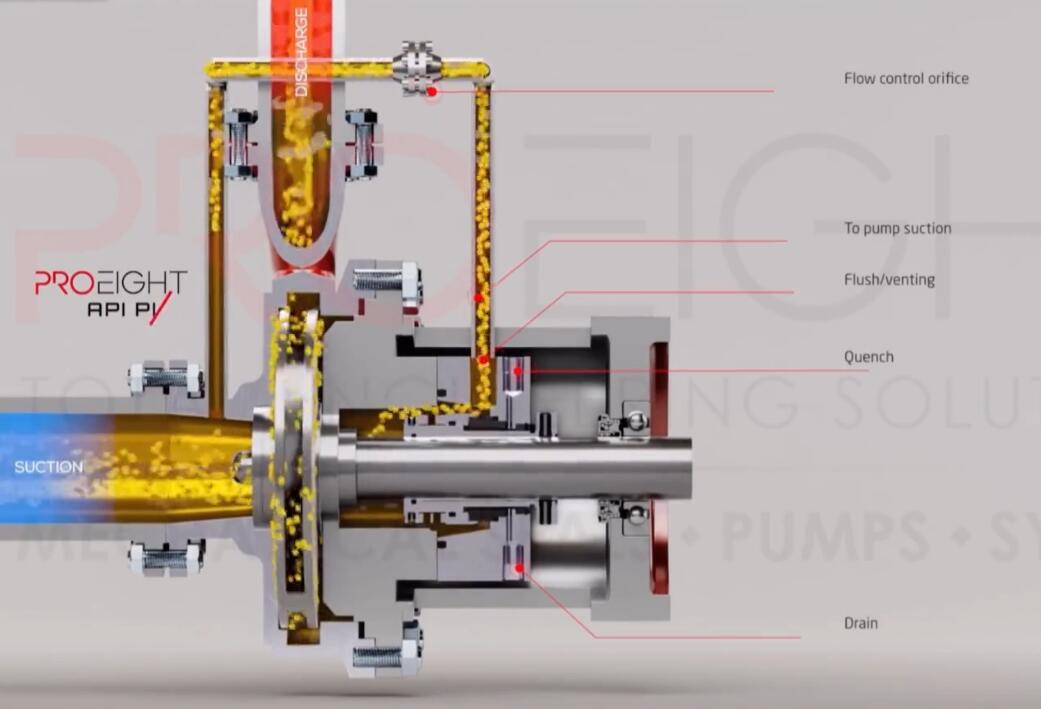

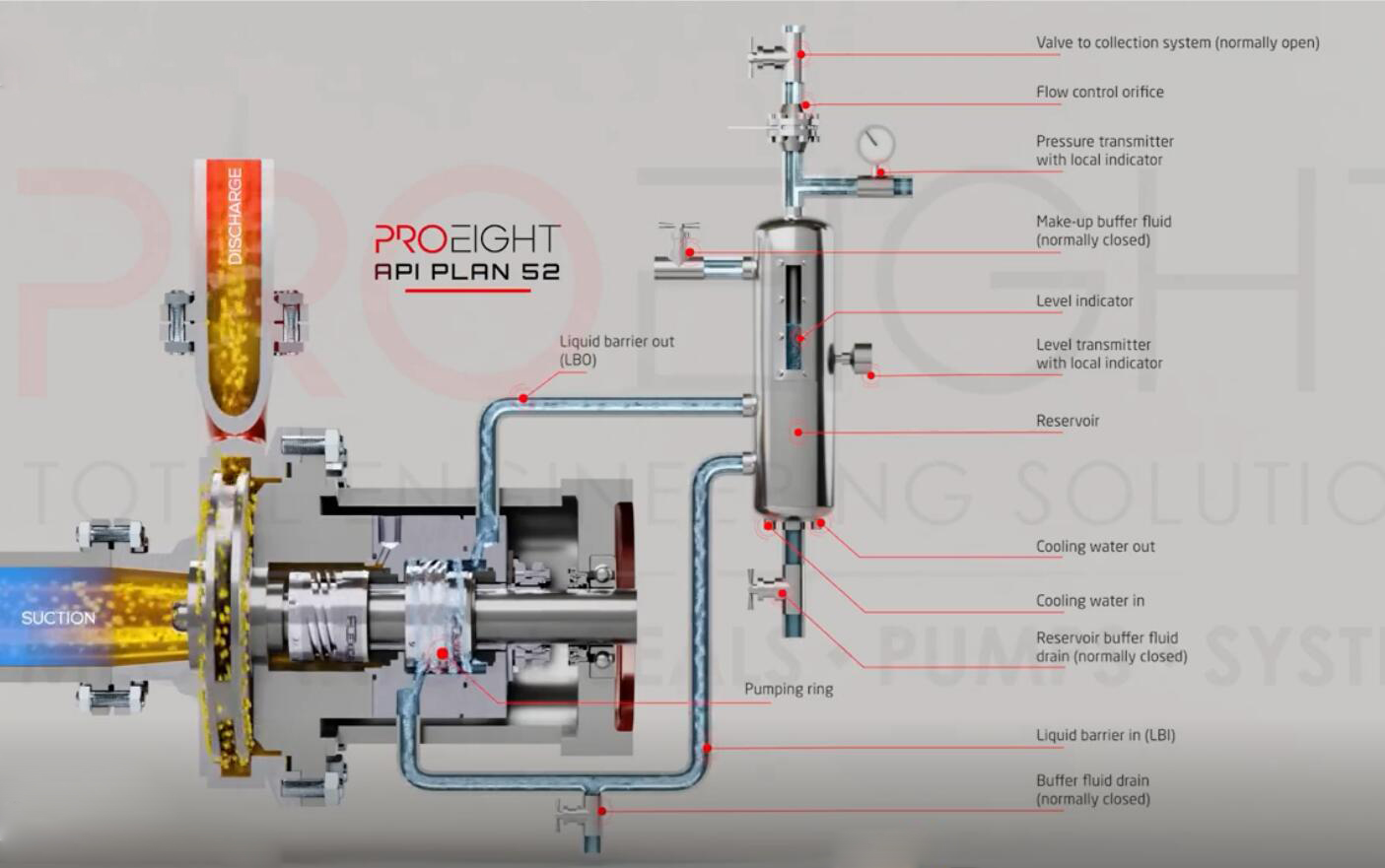

Plan 52: Use buffer solution to isolate and seal the medium, suitable for hazardous media.

Application scenarios

High temperature medium: suitable for high temperature working conditions, isolation liquid helps dissipate heat.

Corrosive media: Isolation fluid prevents corrosive media from contacting the sealing surface.

Containing granular media: The filtration system prevents particles from damaging the seal.

Plan 53: Provide pressurized buffer solution through external system, suitable for high-pressure and high-temperature media. Composed of a series seal or double end face with isolation liquid, a pressurized external isolation storage tank is used to supply clean circulating liquid to the sealing tank. The storage tank pressure is generally 10% higher than the sealing medium pressure and is suitable for the following conditions:

*Cannot leak into the atmosphere

*Dangerous, toxic, and flammable fluid media

*Wear resistant, with particles

*Fluid conditions such as easy crystallization

Flush the mechanical seal to dissipate heat and reduce liquid temperature. The P LAN35 solution is equipped with a pressure switch and a liquid level switch. The pressure of the sealed tank is higher than the pressure of the sealed medium. When the internal or external seal fails or the pressure source pressure decreases, the pressure of the sealed tank will drop, triggering the pressure switch, activating the alarm or shutting down the equipment.

Plan 53 is commonly used for the following operating conditions:

High pressure pump: such as the high-pressure feed pump in a hydrocracking unit.

High temperature pump: such as the hot oil pump in an oil refinery.

Corrosive media: such as acid and alkali pumps in chemical production.

2.2 Selection of Rinse Liquid Cleanliness: Ensure that the flushing solution is free of particles and impurities. Compatibility: The flushing solution needs to be compatible with the medium and sealing material. Temperature: The temperature of the rinsing solution should be within the tolerance range of the sealing material. 3. Comprehensive consideration Safety: Ensure that the sealing and flushing system can still operate safely in abnormal situations. Economy: Choose a low-cost solution while meeting the requirements. Maintainability: Choose a system that is easy to maintain and replace to reduce downtime.

conclusion

When selecting the sealing and flushing system for chemical pumps, it is necessary to comprehensively consider the characteristics of the medium, operating conditions, material compatibility, and economy to ensure the safety, reliability, economy, and ease of maintenance of the system.

- Pre:None

- Next:The selection method for the s 2025/2/21